Background

Local Area Network (LAN) campus and building backbones as well as Data Center backbones are migrating to higher cabled fiber counts to meet increasing system bandwidth needs. In many cases, Ribbon Fiber Cables are now being deployed to meet this need, as they provide the highest fiber density relative to cable size, maximize use of pathway and spaces, and facilitate ease of termination.

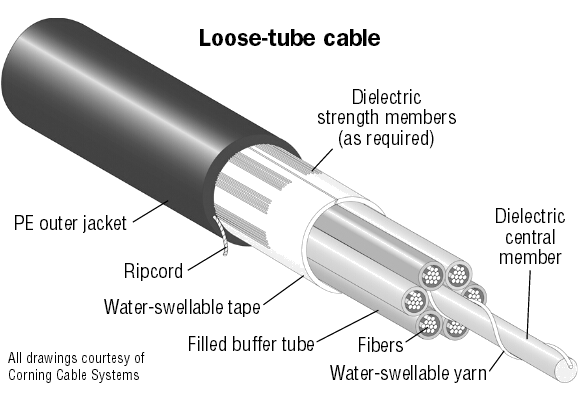

Stranded loose-tube cable has been the dominant fiber optic cable design deployed in campus backbones for more than 25 years. In recent years, this design has also emerged as a major choice for building backbones where riser and plenum flame ratings are required. The loose-tube cable has demonstrated exceptional and reliable mechanical, environmental, and optical performance that has been unmatched by any other optical cable designs and other media types. Loose-tube design typically consists of multiple buffer tubes that contain up to 12 fibers and are stranded around a central member. High tensile strength yarns are helically applied around the stranded buffer tubes. Contingent upon the deployment location, a non-flame or flame-retardant jacket is applied. Recent technology innovations have resulted in a completely gel-free design that contains no filling or flooding compounds, eliminating the time and labor associated with cleaning and terminating fibers.

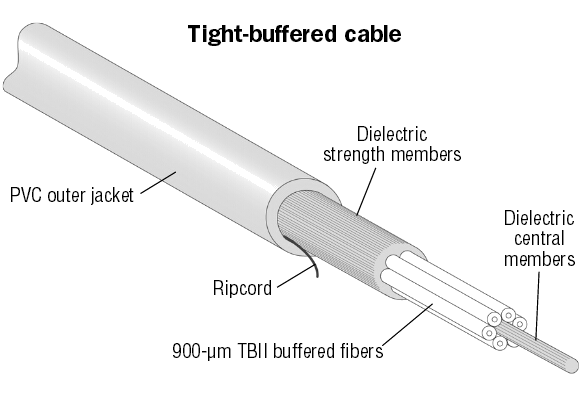

Historically, tight-buffered cables have been limited to indoor premises applications. The cable normally has been deployed in low-fiber-count (24 or fewer fibers) building and data center backbone and interconnect (two fibers or fewer) applications. The cable design typically consists of multiple 900μm tight-buffered fibers stranded around a central element, with tensile strength yarns and a flame-retardant jacket applied. (Related products sample in Fiberstore: 900μm Tight-Buffered Fibers)

The Ribbon Unraveled

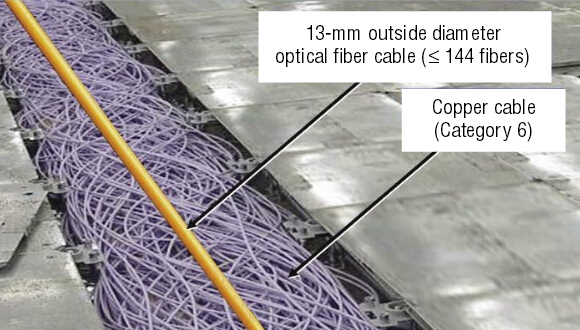

Ribbon fiber optic cable has recently emerged as a primary cable choice for deployment in campus, building, and data-center backbone applications where fiber counts of more than 24 are required. This design offers robust performance equivalent to the stranded loose-tube cable, and provides the maximum fiber density relative to cable diameter when compared to stranded loose-tube and tight-buffered cable designs. (The following picture shows that a simulated fiber optic cable with up to 144 fibers is superimposed over a cluster of copper cables, depicting the space savings that optical transmission can achieve in high-density areas, such as data centers.)

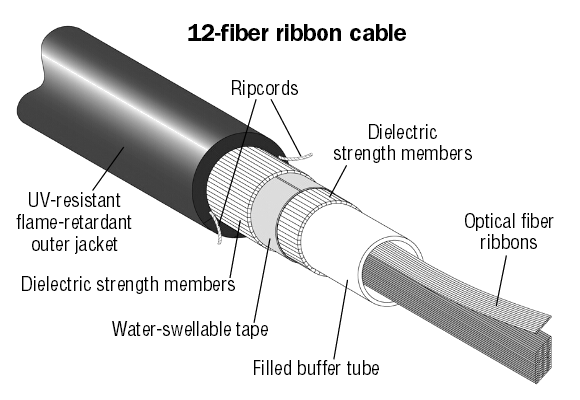

The ribbon cable design characteristically consists of 12 to 216 fibers organized inside a central tube. For indoor designs, helically stranded strength elements provide tensile strengths of up to 600 pounds. The 12-fiber ribbons are readily accessible and identifiable with ribbon identification numbers and TIA-598-compliant fiber color-coding.

A non-flame-retardant jacket material is typically used in outside plant applications. Specially formulated flame-retardant outer jackets are used for indoor applications so that the cable design meets the requirements of the NFPA-262 flame test for ribbon plenum cables, as well as the requirements of the UL-1666 flame test for ribbon riser cables. Like the stranded loose-tube cable, completely gel-free designs are available.

For many years, designers and installers have been reluctant to specify ribbon fiber optic cable in the LAN and Data Center because 12-fiber ribbon field terminations were limited. But with the introduction of innovations such as ribbon-splitting tools, ribbon-furcation kits, and field-installable 12-fiber array connectors, 12-fiber ribbons can be easily terminated with simplex and duplex connectors (such as LC or SC type) or with the MTP array connector.

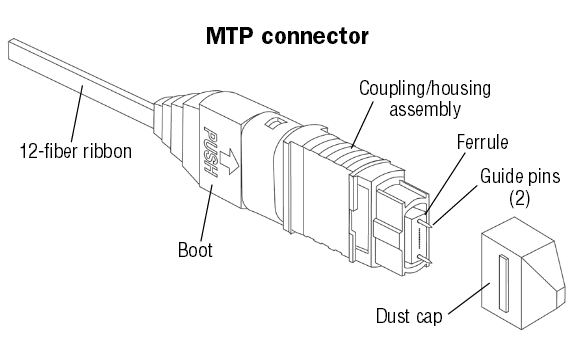

The MTP connector is a 12-fiber push/pull fiber optic connector with a footprint similar to the SC simplex connector. These high-density connectors are used to significantly accelerate the network cabling process, minimize errors, and reduce congestion in patch panels.

The MTP connector is commonly available in preterminated form—as a pigtail to be spliced onto a 12-fiber ribbon, or as an MTP connector backbone assembly that is terminated on each end. Field-installable MTP connectors are also available with a no-epoxy, no-polish design that lets you terminate 12 fibers in less than five minutes. The MTP connector is specified to conform to the TIA/EIA-604-5 intermateability standard.

Many end-users are now using factory-terminated cables with MTP and/or simplex or duplex connectors to ensure the highest quality connector insertion-loss and return-loss performance, as well as to expedite cable installation. This is especially true in the data-center environment where short-cycle installations and limited time availability for moves, adds, and changes make simplified and fast installations critical.

MTP connectorized ribbon cable typically is terminated in patch panels using one of two methods:

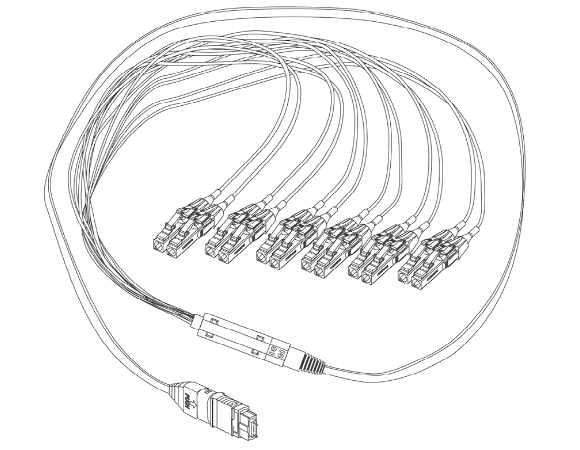

- Method 1 is normally used in an interconnect application where a harness assembly is used on the front of the patch panel. Harness assemblies are used to break out the 12-fiber MTP connectors terminated on ribbon cables into simplex- or duplex-style connectors. Harness assemblies have MTP connectors on one end of the cable while the other end is equipped with simplex or duplex style connectors. The harness assembly interconnects with the backbone ribbon cable at the patch panel MTP connector adapter. (Related products sample in Fiberstore: MTP Harness Cables)

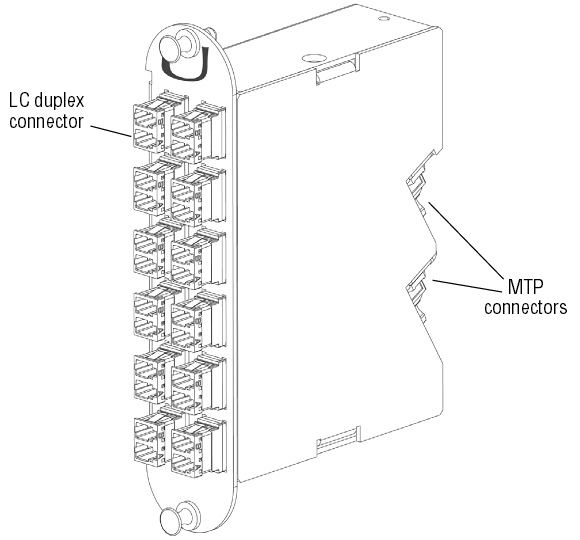

- Method 2 is used in both interconnect and cross-connect applications where an MTP connector module is used. MTP connector modules are used to break out the 12-fiber MTP connectors terminated on a ribbon cable into simplex or duplex style connectors. Simplex and duplex style fiber optic patch cords then can be used to patch into system equipment ports, patch panels, or client outlets. The module features simplex or duplex port adapters across the front and one or two MTP connector adapters across the back. Fiber polarity is maintained with an integrated wiring scheme built into the module that ensures proper transmitter-to-receiver continuity throughout the system; so, when end equipment patch cords are installed, transmit goes to receive. (Related products sample in Fiberstore: MTP Cassette Modules)

Pathway and Spaces

It is critical to maximize use of pathway and spaces, especially in campus and data-center backbones where space is a premium. Ribbon fiber cables offer up to 45 percent space savings, and three times the fiber-tray capacity over traditional bulkier cable solutions while minimizing cable tray weight. Optimal cabled fiber density in data-center pathway and spaces is important to facilitate efficient cooling systems as well as for removal of abandoned cable in accordance with the National Electrical Code.

In summary, ribbon fiber optic cable is now being deployed in areas where stranded loose-tube and tight-buffered cable have historically been used. Ribbon cable offers the highest fiber packing density to maximize pathway and space utilization in ducts, raceways, and patch panels. Preterminated or field-terminated ribbon cable is now easily obtained using traditional simplex or duplex connectors, as well as the MTP array connectors.