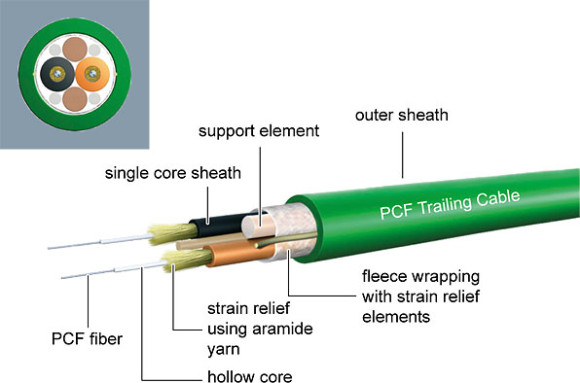

When talking about large core optical fiber before, my first thought was the plastic optical fiber. However, later, I saw large core glass fibers in many places on the Internet. And now, I would like to tell you the truth. Large core optical fibers include two types: Plastic Optical Fiber (POF) made from light-conducting plastics and Plastic-Coated Fiber or Polymer Cladding Fiber (PCF) whose core is made of glass. POF has been talking about so often that I will just introduce the PCF to you in this article.

The PCF is made from silica glass with polymer cladding, and is excellent for transmission of high density optical energy from ultraviolet rays to near infrared rays. PCF features with a superior guide for laser beams and a wide range of wavelengths for applications which require high power optical energy. For example: laser processing machinery and laser cutters, fiber optic sensors, analyzers etc.

For configuring optical networks, the conventional optical fiber (made from silica glass) is used for long distances, while the large core glass fiber (i.e. the PCF) is used for short distances. Simple fiber optic cabling directly at the machine is implemented using the SC RJ connection system for PCF cables as well as POF cables. In order to ensure high availability, the PCF cables are monitored during commissioning and runtime for any attenuation resulting from material aging.

Benefits from their features, PCF cables can be used in many applications. The following part shows this.

|

Features:

|

Applications:

|

As medical applications are demanding optical fibers to transmit with increasingly higher peak powers and smaller bend diameters, it has become necessary to test and develop fibers that can perform under these strenuous conditions. Recently, a study examined laser damage to large core multimode glass optical fibers (i.e. the PCF) from high peak laser power, providing important insight into the damage mechanism for a particular failure mode. A two-point bend tester was used on fiber samples prepared with polymer coatings, having different refractive indices. It was found that peak power was one of the main determining factors in performance among the samples. Polymer coatings with lower refractive indices were found to significantly improve fiber resistance to bending while transmitting.