Over the past few years, optical fiber cables have become more and more affordable, since they are ideal for networking systems where the transmission of high data-rate at large amount is demanding. Actually, when talking about optical fiber cables, you may be confused about their several standards of classifications, such as connector construction standard and transmission media standard. And this post will classify fiber cables by their cable design standard: loose-tube cable vs. tight-buffered cable.

Loose-tube cables are optimized for outdoor applications. The configuration of loose-tube cable comprises of a coated fiber placed within a loose tube, which is filled with water-resistant gel to protect fiber from tension and stresses caused by such harsh environment as moisture and a wide operation-temperature range from thermal shock to ice loading. That is to say, the gel within the loose-tube construction stops the penetration of water and keeps it away from the fiber, making loose-tube cables suitable for hostile outdoor environment.

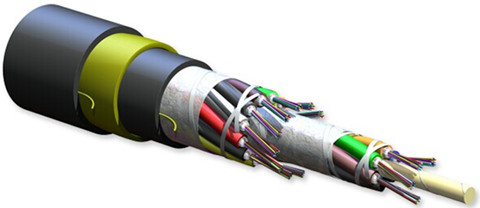

Although loose-tube cables are subject to tough environmental conditions, they are not applicable when cables need to be submerged or where cables are routed around multiple bends. In such cases, the excessive cable strains can force fibers to emerge from the gel. What’s more, loose-tube cables are not ideal for LAN/WAN connections where reliability and attenuation stability outweigh their resistance to humidity and unfavorable temperature conditions. The following image shows a loose-tube cable.

Instead of a loose tube, the fiber may be embedded in a heavy polymer jacket, commonly called tight-buffered construction, which has a two-layer coating. One is the soft plastic that allows deformation and reduces forces endured by the fiber. The other is the hard outer buffer to provide physical protection. Tight-buffered cables, in contrast, are preferred for indoor applications. They are mostly applied in breakout cables and distribution cables.

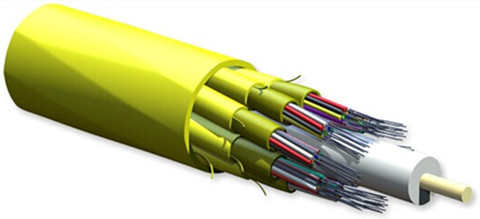

Tight-buffered cables have a smaller package compared with loose-tube cable, and are easier to install as there is no need to clean up messy gel. In addition, the tight-buffered structure create subunits which can be divided among many terminals without using patch panels. However, these tight-buffered cables are not subject to extremes just like loose-tube cable. Fiber expansion caused by temperature extremes and water penetration are potential problems for tight-buffered cables. A figure of a tight-buffered cable is just below.

The application and installation environment decide which kind of cable design should be used. Each of these two designs have their own characteristics. In loose-tube cables, a high level of isolation from water penetration and extreme temperatures are possible, while tight-buffered cables, being more robust than loose-tube cables, are better suited for LAN or WAN connections, long indoor runs and direct burial. Fiberstore supplies both loose tube and tight-buffered cables available in different types, such as 900um tight-buffered fibers and gel-filled loose tube cables. You can visit Fiberstore for more information about them.